Foam Core Types in Sandwich Panels: EPS, XPS, and Polyisocyanurate Breakdown

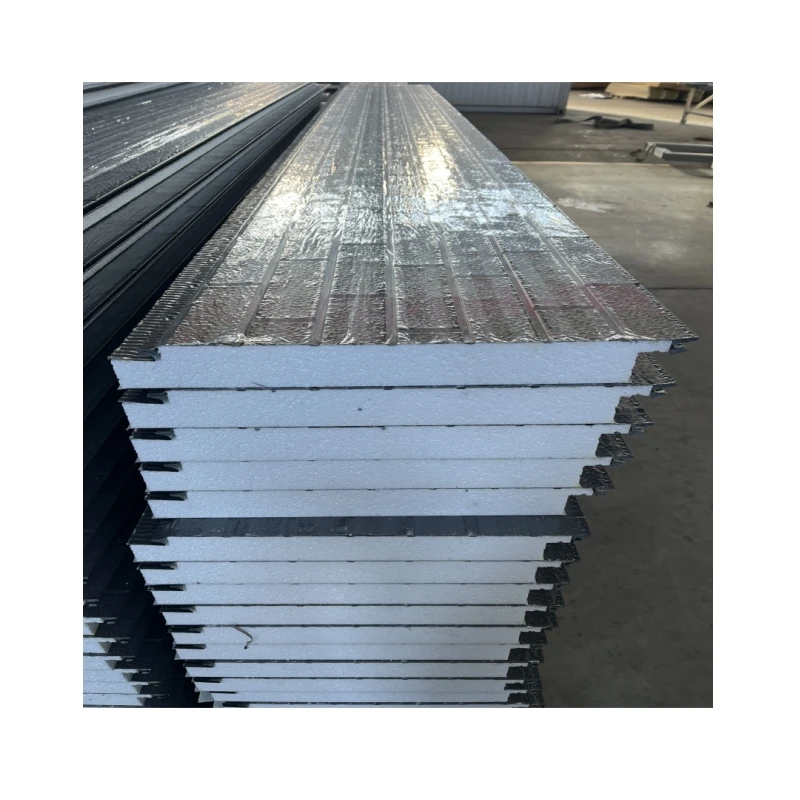

When we construct things such as houses or other structures, we need to consider what materials we will use. One typical is foam core, commonly used, for instance, in sandwich panels in construction. The foam core also keeps things insulated and strong, a plus for many applications.

There are several varieties of foam cores available for use in sandwich composites. The 3 most common types of insulation are EPS, XPS, and Polyisocyanurate. All of them have good points and bad, so it helps to know the differences before deciding which is right for your project.

EPS Foam Core: This is also known as expandable polystyrene. Additionally, it’s light and not too spendy. But unlike many green positives, eps sandwich panel is perfect for keeping buildings warm or cool, and that can be a money-saving asset. But it is not as strong as certain other varieties and may not be best for you if you need very strong something.

XPS Foam Core: This variety is extruded polystyrene. It's a little bit denser and stronger than EPS. This is because it is much stronger and therefore is a popular choice for walls or roofs where additional strength is desired eps panel sandwich is also mold resistant, which can prevent mold from growing in a building.

Polyisocyanurate Foam Core: This is the priciest of the three, but it’s also the strongest and most durable. It does an excellent job of insulating buildings to keep them warm or cool, and resists fire. This type is commonly found in commercial buildings or nice homes where safety is an issue.

All foam core types have their pros and cons, so consider your project before making a selection. EPS could be best for a project with an emphasis on saving money, with XPS being better for a project that requires more strength. Polyisocyanurate works very well for projects that have a very high emphasis placed on safety particularly durability.

When you select foam core for your aluminium sandwich panel project, consider what your project requires. Factor in costs, strength, insulation and fire safety to determine which one is best for you. The two have their respective pros and cons, and it never hurts to take a little time to get more used to how they work, before making a decision.

ETS, XPS, Polyisocyanurate are the three most popular foam cores for sandwich panels. Any variation or genre has its own pros and cons, so consider what you’re looking for in your project before deciding. No matter if you are looking for something budget friendly, super strong or extra durable, there is foam core type that you need for your project the most. Keep in mind the pros and cons of each of these types before you make your decision.

At SDQIGONG We know choosing the right building materials for your construction project is important. Our professionals can help you determine which foam core type is right for your sandwich panel application. Call us now to find out how we can help you with your construction requirements.

Comments

Post a Comment