The Role of Mask Aligners in Semiconductor Device Fabrication

In the world of creating minuscule electronic parts that perform big tasks in things like computers and smartphones, mask aligners are very significant machines. These are the machines that help ensure that everything is lined up exactly right every time we produce these parts. Let’s find out more about how mask aligners work and why they are so important for the stuff we use all the time.

What are Mask Aligners Used for in Electronic Manufacturing

Try to color inside the lines of a picture, but the lines are constantly moving. That’s how it feels when producing microscopic electronic components without Automatic eutectic patch. These are special rulers that hold everything steady when you make these parts. Precision alignment, in which all the pieces of a puzzle fit to make a complete picture. Without it, the electronic bits might not actually work, or they might even break!

How Mask Aligners Are Used to Make Precise Electronic Components

Mask aligners employ terminal insertion machine similar to stencils, which project tiny patterns onto semiconductor materials. Think of it as using cookie cutters to turn dough into various shapes. The design of these patterns must be just right if the electronic parts are to work as intended. The mask aligners ensure that that these patterns are placed exactly where they should be on the materials.

Applications of Mask Aligners in Pattern Generation

Patterning is akin to making a pattern, like stripes or dots, on the semiconductor materials. Its important all these patterns are nice and neat so all the electronic parts could do their correct job. Good solid mask aligners are essential to the precision of allowing these patterns to be formed exactly as they should. This precision is what’s crucial in keeping the electronic parts operating smoothly.

State of the Art. Mask Aligners

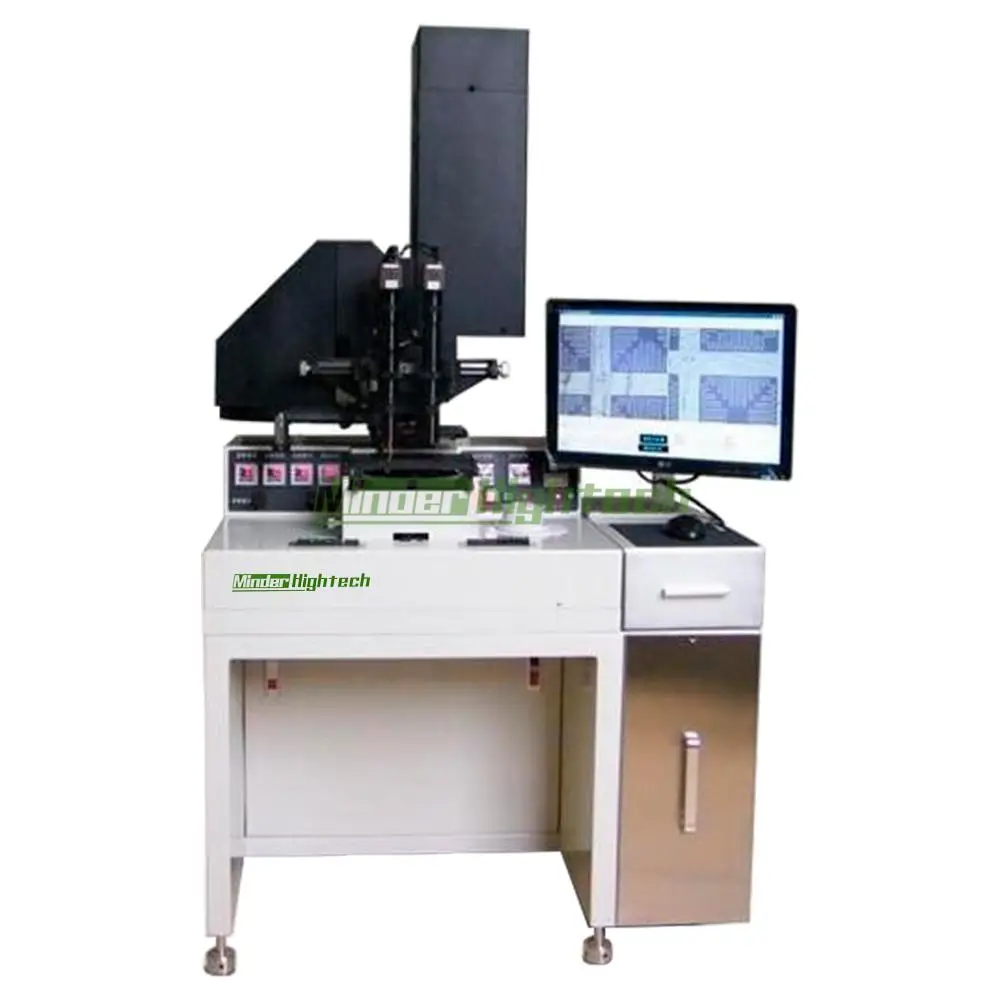

The camera is always getting better, and Terminal insertion are part of it! State of the art technology applied in mask aligners, means that even more detailed, and accurate, patterns can be made on semiconductors. This indicates that electronic components can be fabricated more accurately and with a high yield. We at Minder-Hightech are constantly comparing and enhancing our mask aligners for the best possible results.

Electronics Speed Up, and Much More Consistently

It’s like trying to bake a whole lot of cookies and not having a cookie cutter. It would be difficult to ensure that every cookie was the same size and shape. Mask aligners speed up the process and ensure uniformity in semiconductor production as they ensure that every electronic part is made in the same way each time. This allows lots of parts to be made quickly and consistently.

Conclusion

In short, maskers are secret weapons in the production of tiny electronic parts. They help to hold everything in place, make precise patterns and make electronic parts work well. Minder-Hightech is continuously advancing their mask aligners, and who knows what amazing things they will enable in the future!

Comments

Post a Comment